Drones: the small beginning of something big

Some time in 2018 during my senior year at the University of Waterloo I read about the “GoFly” challenge, a Boeing sponsored competition with a $1MM prize for whomever builds a small and quiet VTOL aircraft. I had a friend who had been talking about flying contraptions since first year, so we decided to partner and build such a vehicle.

Given the fact that we were students, we used all the resources around us to our advantage: we based our senior design capstone project around the competition (grades + funding to work on the project), and also launched an engineering student design team to help design the aircraft (free labour + potential future hires).

Before we could build a people-carrying aircraft we had to start small: drones. We spent around a year designing and building drones, plus coding software for these, building a business plan for the future aircraft, and raising a bit of capital. Because Watfly is still operating today, I will refrain myself from going too deep into the details, but here are some pictures of the first prototypes:

GoFly scoring criteria.

First, for design context, the GoFly scoring criteria above. It focused on size (with a maximum of 8.5ft on the longest dimension), noise (maximum of 87dBA at 50ft), and speed (minimum of 30 knots), while requiring take-off to occur in a tight envelope (STOL, close to VTOL). Keep in mind this is for a single passenger aircraft, and there was also an implied range specified by their flight circuit which was 6 nautical miles long plus a 10 minute endurance reserve.

The design process goes something like this: How many propellers (Yes, propellers. Turbines would never meet the noise constraint) do I need to fly a single person? Can they fit within the size specified? This is followed by: How efficient will flight be? Can hover flight endure the flight circuit or do I need wing-borne lift? Lastly, how much energy do I need? And then iterate through this loop a few times (your propellers need to lift your energy storage systems, and so now they are more power hungry and you need more energy, you get the idea).

Controls experiment swing.

3D printed propeller + stator.

Before building any drones, we tackled the individual systems were we saw the greatest design risk. Having spent the last years building composite structures, the airframe was a low risk item for us but the control system and propellers would require learning. We dived deep into control systems theory and the design of propellers and aeroacoustics, plus ran some in-house experiments. Above our controls swing, a simple 1-DoF system which balanced a swing horizontally using a PID loop through the thrust differential of two propellers on the sides. We also 3D printed propellers and stators and used these to validate our computational models through RPM, thrust, torque, and acoustic measurements.

MAVIS getting primer sprayed on.

MAVIS on its final form.

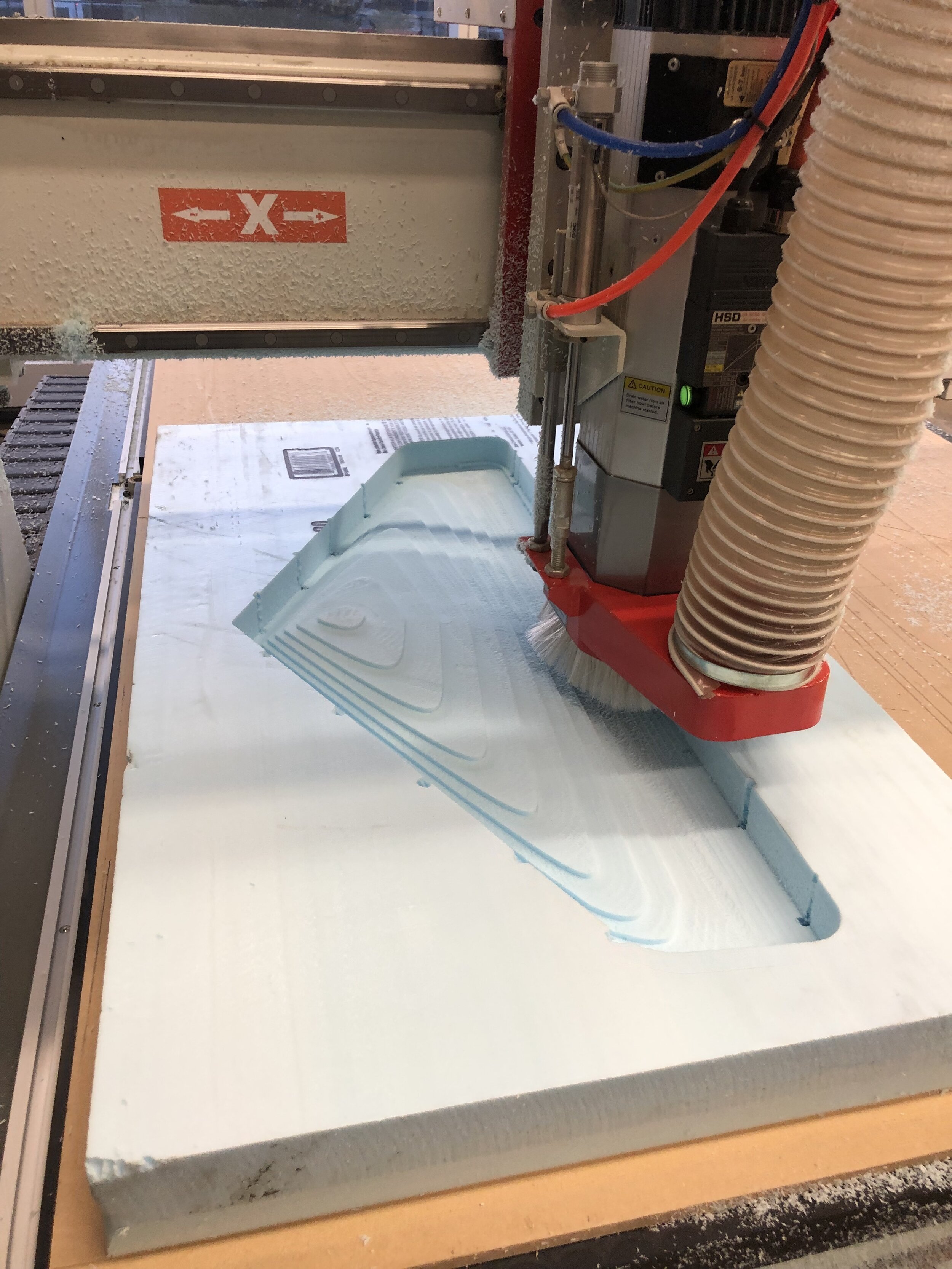

Our first drone was MAVIS, a quad-rotor, tilt-wing configuration. It would take-off vertically and then rotate its wings and propellers forward for horizontal wing-lift assisted flight. We built the passenger cell out of fibre glass and epoxy resin through a wet layup process on a CNC’d poly-urethane foam mould. The wings were 3D-printed and coupled to a servo motor through an aluminum shaft for the rotating motion. All of the motors, motor controllers, servos, telemetry radio, propellers, and batteries were bought online at drone hobby stores (it’s remarkable how far the hobby drone community has come). The brain on board lived in an off the shelf PX4 board running custom firmware built on top of Pixhawk open source flight controller, specifically for our airframe configuration.

This was the first time flying anything for most of the team and the learning curve was steep. We struggled with controlled take-offs, dealing with wind gusts, and maneuvering the drone in the air. Crashes were a common occurrence, repairs got costly and time consuming, this drove our next iteration.

MAVIS in its natural tether position.

MAVIS first take-off.

Take-off outside of ground effect.

A few dozens of crashes later we iterated to MAVIS 2.0, a sheet metal drone. The thought here was that it would be easier to repair and also lighter, granting us higher thrust margins and controls authority. For the most part this was a good next step. I will warn you that electrically insulating your metal airframe is crucial, and said insulation must withstand crashes, don’t ask me how I know.

MAVIS 2.0 Airframe.

MAVIS 2.0 on the tether, sans props.

Having built our first drone, conducting tests, and validating our initial models, we started to look for areas of big improvement. The team moved from the original tilt-wing quad-rotor design onto a dual-rotor tail-sitter. Within the spatial constraints indicated by GoFly, a lower rotor count seemed optimal in order to maximize the rotor size and ultimately minimize disk loading (which was key for the hover take-off and landing, as well as to keep power consumption within a realistic range). Similarly getting rid of the mechanical complexity and mass of the tilt mechanisms improved our vehicle’s overall performance. On the other hand, controls would get tougher as we could no longer rely solely on thrust differentials to maneuver the vehicle, but would rather use blown control surfaces. You can see a render of the vehicle below, and on hindsight the team’s decisions were accurate and we saw other teams converging on similar configurations as the GoFly competition progressed.

Above you can also see some of the systems design schematics for such aircraft, including the passenger cell, the computer system, and the power system (if I have not mentioned this before, this was meant to be an electric aircraft). At the end of the day, yes we were building really scrappy sheet metal and foam drones, but the engineering behind them went deeper than one could appreciate by just looking at our prototypes (and I believe this is often true for hardware companies).

We continued to validate our designs through scaled down drone prototypes, this time moving away from sheet metal onto foam. This was by far the lightest, cheapest, compliant, and easiest to repair material available.

It was also around this time when the GoFly competition started to leave us behind. Other teams had by now validated their designs and started building full-scale vehicles with much bigger budgets than we had. Looking back, it was not so much that we could not crack the problem, but rather that we could see that without these artificial competition imposed constrains, we could build an aircraft with very compelling properties for real life applications. At the same time, my friend and I were both graduating from our undergrad which meant the end of the student team, and this eventually led to us dropping out of GoFly. The GoFly competition took part in 2019, and we were not surprised to see that no one took the prize. In hindsight, we dodged a huge bullet: spending years and hundreds of thousands of dollars to develop an aircraft with no real application, looking back I am perplexed why someone would think that is a good idea.

CNC’d a foam wing.

Dual-rotor foam drone.

Drone taking off.

After a few months of finishing school, we went back to the drawing board. This time not as a student team, not pursuing a competition, and with no resources to back us up but rather two engineers working in a garage with a dream to fly.

We were able to sell the dream and raise a bit of money through pitch competitions and awards. My then co-founder won the Velocity $5k pitch competition with nothing more than a few renders and then went to do the same in the Youth President Organization (YPO) innovation week pitch competition. Simultaneously, we received a small cheque from ANSYS for the work done on the aeroacoustic analysis of our vehicle concept. This was enough to get the ball rolling.

Winning a $2.5k pitch competition.

Winning a $5k pitch competition.

Winning an engineering analysis award.

Having literally crashed and burnt multiple drones by now, we decided to buy an off-the-shelf drone that closely resembled our design and build from it. This would keep us from spending time shaping foam and fitting motors in it and rather spend time in the controller software and the overall handle of the drone which was the priority. You can see below that we were still flying drones in classrooms even though we were not students anymore, this is just because the school did not change the door combinations and we were in the middle of a harsh Canadian winter.

Eventually the controller got good enough and we went back to building our own drones, still similar to the off-the-shelf design but with a bigger wingspan, bigger propellers, and a bigger battery. Our approach this time around was to laser cut foam board (you can get this for $1 at the Dollarstore and it laser cuts really well) and shape it into a drone, plus a couple of 3D printed brackets here and there. The drones would not be indestructible but we could laser cut a new one within minutes and for practically no cost. We built on top of this design for a few months and eventually got to the point where we were doing GPS navigation.

Off-the-shelf drone flight.

But building drones was not what we were after, we wanted to build an aircraft in which we could fly ourselves, and for this we needed more money. I’ve seen a lot of early hardware projects fail at this point, although any company has a chasm to cross in terms of product-market fit, capital intensive companies have a much earlier chasm to cross in terms of securing enough funding to even validate the concept.

We used the same renders that we used to win pitch competitions to secure pre-orders. We then used the pre-orders plus a bunch of the drone footage that we had collected from our last prototypes, to pitch and win the Velocity $50k competition and even landed a Y Combinator interview. Things were starting to look good, and we were ready to start scaling up our aircraft.

Winning a $50k pitch competition.

Y Combinator Interview.