What’s up? This is where I put everything else: small projects that I’ve built or been part of but that don’t warrant individual posts just yet.

Jet Diving: (2020 - 2022)

Have you ever jumped out of an airplane? It goes something like this… You climb on a small plane and go all the way up to 10,000 feet. They open the door and you jump out. For about 30 seconds you are on free fall, questioning your life’s decisions and living life to the maximum. After that your parachute opens and you slowly fall to the ground.

Yup, that’s it, only 30 seconds. Well, what if you want to fall for longer? Jumping from higher altitudes is an option, but it’s more expensive and requieres specialized equipment like an oxygen tank.

What if you could strap two EDFs onto your jump gear and use it to increase your horizontal speed, gliding or even gaining altitude as you fly through the skies? We are building just that. Two brilliant engineers and I started the project mid 2020, so far we’ve sourced components, built dynamic models, and are now in the process of validating our propulsion model with this jig we built that can be mounted on top of my car.

UPDATE: Not working on this anymore, I wrote a full post here!

My First US Patent: (2019)

While studying at Waterloo, I had the privilege of completing multiple internships at Tesla. The first day of my first internship, the company was all hands on deck trying to ramp up the Model X and ship the Model S refresh. The last day of my last internship, we had shipped Model Y and we were working on on the announced Cybertruck and other projects not yet released. In between I got to be part of the Model 3 SOP and ramp up, and the Semi launch. Looking back, I had no idea how impactful these products were going to be.

During one of these internships, I got to work on an electromagnetic windshield wiper system for an unreleased program. Such a system has many advantages but the main one being maximizing the swept area without the need of complex mechanical linkages. Without saying too much, you might be able to imagine why you’d want to sweep a large area in an autonomous vehicle: there are areas that must be swept by law in the field of view of the human passenger/driver, and then there are areas where the cameras are located that you don’t have to sweep by law but want to do so to maintain proper system operation.

We got a US patent granted for this work, US10889267B2. The patent has also been widely covered by the media and there’s a lot of speculation around it. My leaps are sealed. See some of the articles: here, here, here, here, here.

Capstone Project: (2019)

Senior engineering students at the University of Waterloo are required to submit a capstone project in order to graduate. In your capstone you must demonstrate the ability to work in a team, adhere to a budget, identify a need and develop a product to address it (while applying an engineering process that goes from concept creation, analysis, validation, prototyping, and fabrication). It all culminates with a giant report and a “demo” day, with prizes and the perpetual respect of your classmates in the line.

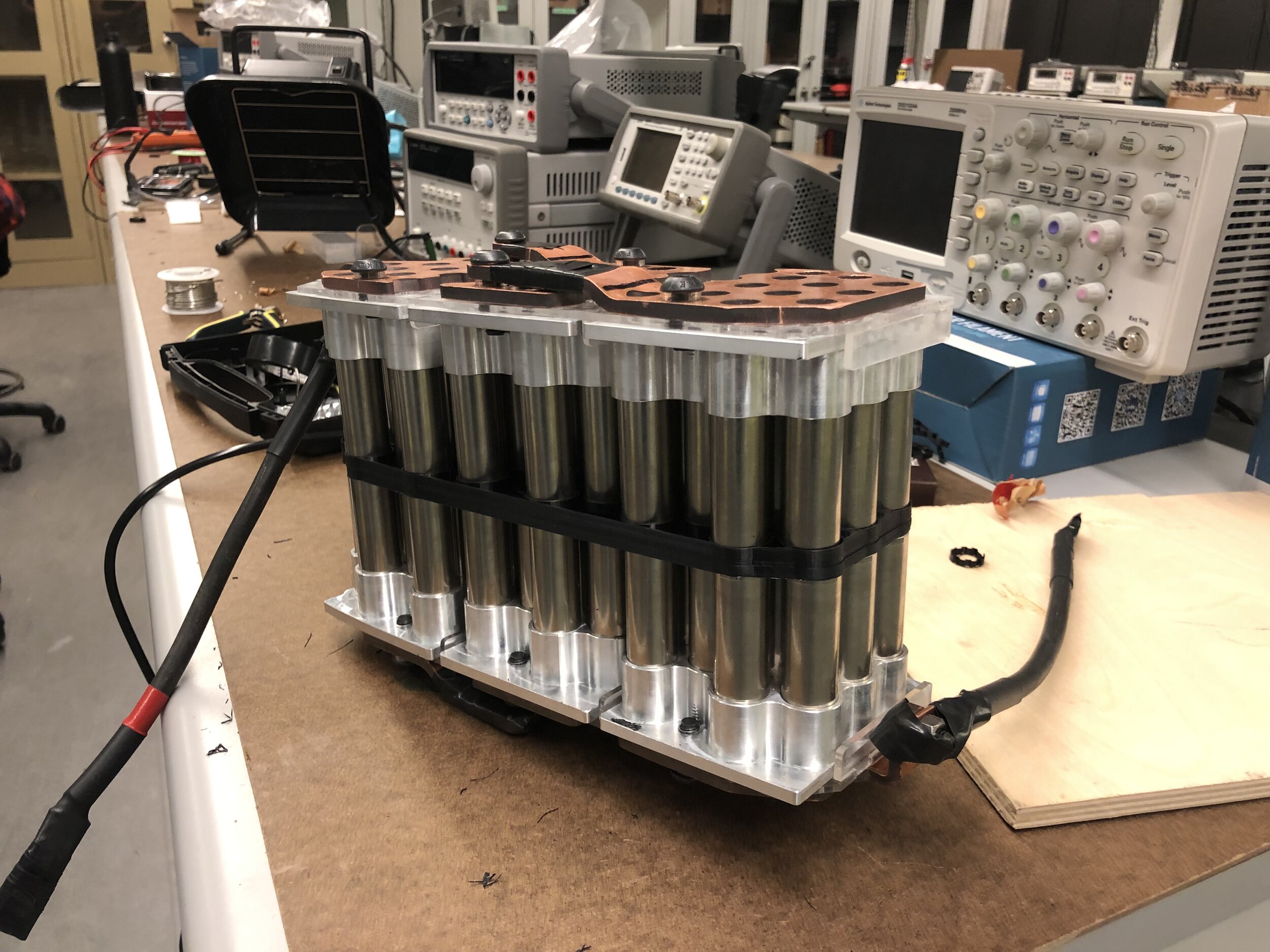

My capstone project was on the development of the powertrain for an electric vertical take-off and landing aircraft. It involved the design, optimization and prototyping of an electric ducted fan (which we actually built and tested), a wing integrated battery pack (which we actually patented), and wings to demonstrated the principle of blown lift in a wind tunnel.

Without going into boring details, the pictures below sum it up pretty well. We won the ANSYS engineering analysis award and got 2nd place in the people’s choice award, not a bad way of ending my undergrad.

Autonomous Snow Plower: (2017)

During an internship at Clearpath Robotics, me and some of the other interns got together to work on an autonomous snow plower after work. We convinced Clearpath’s CTO to give us some funding for the project, plus a Husky robot to use as platform. I designed and fabricated the mechanical systems, including sizing two actuators, the arm and plow mechanism, packaging the LiDAR and battery, and the traction calculations.

Hyperloop: (2015-2017)

In 2016, Elon Musk unveiled his concept of a hyperloop plus announced a SpaceX hosted hyperloop competition. A team of people in Reddit registered to compete under the name of rLoop (which still exists today as global engineering crowdsourced organization). At the same time, my school also registered a team but I thought rLoop was better managed so I joint them.

I helped design the system operations schematics, alternative propulsion systems, and the exterior aerodynamic surfaces (if you think aerodynamics don’t come into play because the hyperloop operates in near vacuum, you are wrong, you can still choke the tube). In 2016 we were the only team to compete with a pressurized interior, and in 2017 we won SpaceX’s innovation award. On top of that, I also helped with the fabrication of my school’s exterior shell, a similar construction to that of my submarines.

The Growing Company: (2017)

My then roommate and I started experimenting with indoor agriculture. We put together these “pods" to grow romaine lettuce in our basement (romaine lettuce has one of the shortest growth cycles out of all crops). This included an automated water recirculating system, pH and temperature sensing and control, UV light intensity optimization, and up to 12 lettuce heads for pod.

I see the opportunity here but it didn’t make economical sense at the time. It came down to robots competing against the cheapest human labour rates on Earth. Plus customers did not seem to care where their crops came from. One day I do foresee indoor agriculture will be a critical part of the food supply chain.

Autonomous Play Mate: (2016)

In 2016 I got invited to Hack the North, the biggest hackathon in Canada. Over a weekend I teamed up with 3 strangers from around the world (one even came all the way from the Philippines, shoutout Keenan!) and built a 3D printed robotic arm that would play rock-paper-scissors and beat you every single time.

This was part engineering, part art. We were trying to make a point that machines would eventually get better than humans at everything.

Learning to CAD: (2014)

In the Winter of 2014, I failed to land an internship and went unemployed for a term (my university requires you 6 internships, the first one starting 4 months after the start of your freshman year, I had no skills). I spent my first winter in snowy Canada glued to my desk, learning how to freehand sketch and 3D model in Solidworks, here are some of my models. By the end of this winter, my portfolio was so stacked you bet I landed a really good internship next term as a design engineer.